These 3 sets of probes are evenly distributed in the circumferential direction of the workpiece, spaced 120° apart, on the same section. Quantity: 3 sets of probes, each consisting of 2 wafers.

Each of the adjustment frames is equipped with a 2-channel combined ultrasonic line focusing longitudinal probe to detect longitudinal defects of the steel tube in a clockwise direction.ĭetection of defects: Vertical and vertical defects in the steel pipe are detected in a clockwise direction. Probe configuration on the spindle section 1Ī total of 3 probe adjustment frames are placed on section 1 at 120°apart.

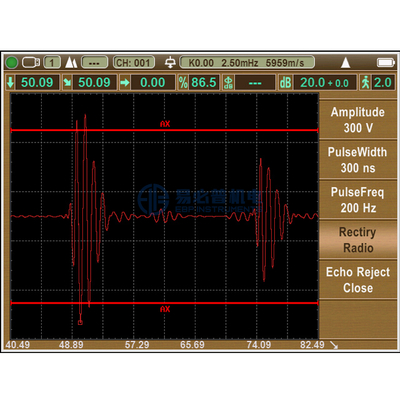

Wireless Transmission Ultrasonic Pipe Testing Introductionġ. The ultrasonic instrument will alarm the ultrasonic reflected signal after realizing the signal to realize the automatic detection of the defect Transmission ultrasonic pipe testing equipment is currently the advanced detection equipment in China. The principle of ultrasonic flaw detection is that after the ultrasonic wave is coupled to the steel pipe through water, the incident propagation will cause ultrasonic reflection when there is a defect in the pipe. The ultrasonic pipe testing equipment system is suitable for the automatic detection of various internal and external defects of steel pipes.

0 kommentar(er)

0 kommentar(er)